BMW M4 with Water Injection Technology

BMW is stepping on the gas to make turbocharged engines even more powerful and fuel efficient. And they have a potent weapon to achieve this – water injection technology.

By Emilio Brambilla

BMW is stepping on the gas to make turbocharged engines even more powerful and fuel efficient. And they have a potent weapon to achieve this – water injection technology.

The technical challenges posed by the need to improve forced induction engines have always been the same – to obtain more power and, at the same time, limit fuel consumption.

Engineers in the past have often resorted to the injection of water into the cylinders. The designers of piston engines used this system for the aircrafts of the Second World War before the wizards of the powerful turbo era of Formula 1 tried their hand at it in the 1980s. Now, it’s the turn of BMW to embrace this technology.

FROM KILLER TO CURE-ALL

While one tank of watered fuel causes significant damage to an engine – fuel pump and injectors blocked by rust – injecting the right quantity of water into the cylinders is often the perfect cure for turbo engines, particularly when working at high loads.

But there are a few challenges, as the project manager for BMW explained to us. You need to prevent engine damage of course, but also develop a system to periodically replenish the water tank in a trouble free manner. For example, you have to prevent the liquid from freezing in winter, and also protect from the corrosive effects of the water that remains in the injectors.

In their quest to fine tune water injection, BMW has carried out a lengthy development process – which started with the M4 that’s used as a Safety Car in the MotoGP racing series.

They also tested the effectiveness of the system on a prototype based on the 1 Series – with a 1500cc, three-cylinder motor. In this application, the system sprays a fine mist of water right into the combustion chamber. While mixing water with petrol isn’t normally recommended, in this case it evaporates immediately and helps cool the engine from the inside – allowing it to run at a higher efficiency. Lower temperatures also reduce the risk of uncontrolled combustion or knocking.

On the track, you can derive the maximum advantage as the engine is pushed to the extreme – which creates ideal conditions that benefit from the presence of water in the combustion chambers.

It’s the perfect solution for intensifying the downsizing that’s currently taking place – i.e. the use of smaller displacement, but more powerful, engines. You get outstanding performance from the turbo while using commercially available petrol.

NO KNOCKING

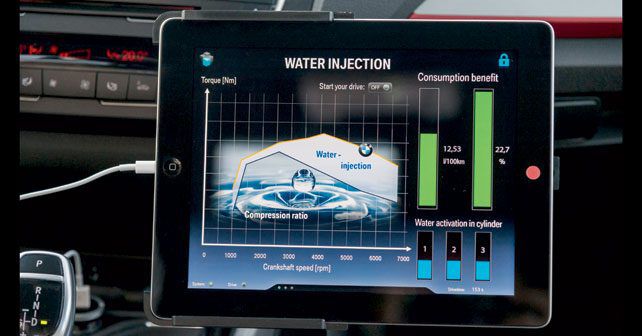

According to experiments conducted by BMW, fuel consumption can be reduced by up to 8%. In addition, the lower tendency of knocking allows the engineers to increase the compression ratio (11.0:1 in the three-cylinder BMW engine, against the usual 9.5:1), with the consequent improvement in efficiency at partial loads (when the car is driven at modest speeds). On the other hand, by combining the optimum values ??of the advance ignition of the spark plugs to a higher boost pressure, you can increase the torque and power of the engines by up to 10%. The three-cylinder, for example, can go from producing 204bhp to 218bhp without flinching.

Moreover, the lower combustion temperatures also reduce polluting agents – especially those like the nitrogen oxides (NOx), which are targeted by Euro 6 regulations. Not to forget that the cooling effect reduces the stress on the pistons, valves, catalyst and the turbocharger. The benefits of direct water injection cooling can be utilised in various ways. Depending on vehicle type and engine, it’s possible to either increase power or enhance fuel economy.

On the 1 Series prototype at the track, there was a water consumption of just 1.7 l/100km, with the injection activated only at speeds above 180km/h, or when at full throttle. The overall fuel saving during the test, in scorching temperatures on the track, was 18.6%. To ensure the supply of water, the BMW M4 MotoGP safety car is equipped with a reservoir of five litres in the boot that has be manually refilled.

On future production models, the water produced from air conditioning will in fact be more than enough to fill the tank unless it’s being driven in a particularly extreme climate. When the atmospheric air is at 20°C, with a moisture content of 60%, the tank can collect about half-a-litre of water per hour. Arguably, these injection systems will soon be adopted by hi-tech road cars – this time, in the name of the war against CO2.

Water and methanol – this is the composition that BMW concocted in the 1940’s to increase the performance of its 801 aircraft engine – a 14-cylinder that produced 2,000hp. Daimler-Benz did the same with the 605 V12 (used by Messerschmitt aircraft) that used 90-octane petrol and rode the MW50 system, which injected fuel and a mixture composed of 50% water and 50% methanol into the cylinders. That solution, in addition to ensuring a high antiknock, helped to avoid the risk of ice formation at high altitude. A similar system was adopted for the R-2800 18-cylinder of the American Company Pratt & Whitney.

The injection of water mixed with petrol was later used by the F1 Ferrari 126 C3 in 1983 – which produced more than 600 horsepower from a twin-turbo 1,500cc V6. But the car that won the Formula 1 championship that year, the BMW four-cylinder turbo powered Brabham, did not employ water injection. It’s another story that Brabham ended up on trial for the suspected use of petrol with an octane rating higher than what was allowed.

DB 605 MW50 1944

In the picture above you can see theV12 of the Daimler-Benz 605, piston aircraft engine of 35.7 litres, equipped with a centrifugal compressor and Bosch mechanical direct injection. The power output at take-off was 1,800hp, thanks to the MW50 system, which added a mixture of water and methanol in equal parts to the petrol.

Used by Formula 1 drivers Patrick Tambay and Rene Arnoux, the Ferrari 126C3 had a water injection system to increase the reliability and performance of the1,500cc V6 that produced more than 600bhp.The solution was not followed because, from the following season, it was banned by the FIA.

MORE EFFICIENCY IF THE IGNITION ADVANCE IS OPTIMAL

The torque output of a motor is the result of the thrust exerted on the piston crown, which depends on the pressure reached during the combustion phase in the cylinders. The cooling produced by the water injected into the combustion chambers runs the risk of detonation (which would damage the piston and the head) allowing engineers to avoid delaying the advance angle of the air-fuel mixture with respect to the optimal value (which is the time where the first spark happens) – with the advantage of obtaining a higher combustion pressure. In other words, achieving a higher driving torque, as well as lower fuel consumption.

The water injection in the 1 Series prototype was done when high torque was required – particularly at medium and high speeds. In this case, the internal cooling brought down the consumption by 22.7%, to 12.53 l/100km.

In the picture, you can see the prototype 1 Series, with its three-cylinder petrol engine that has water injected directly into the cylinders. Below, the Concept M4 GTS, special series six-cylinder turbo on which the new technology debuted.

© Riproduzione riservata